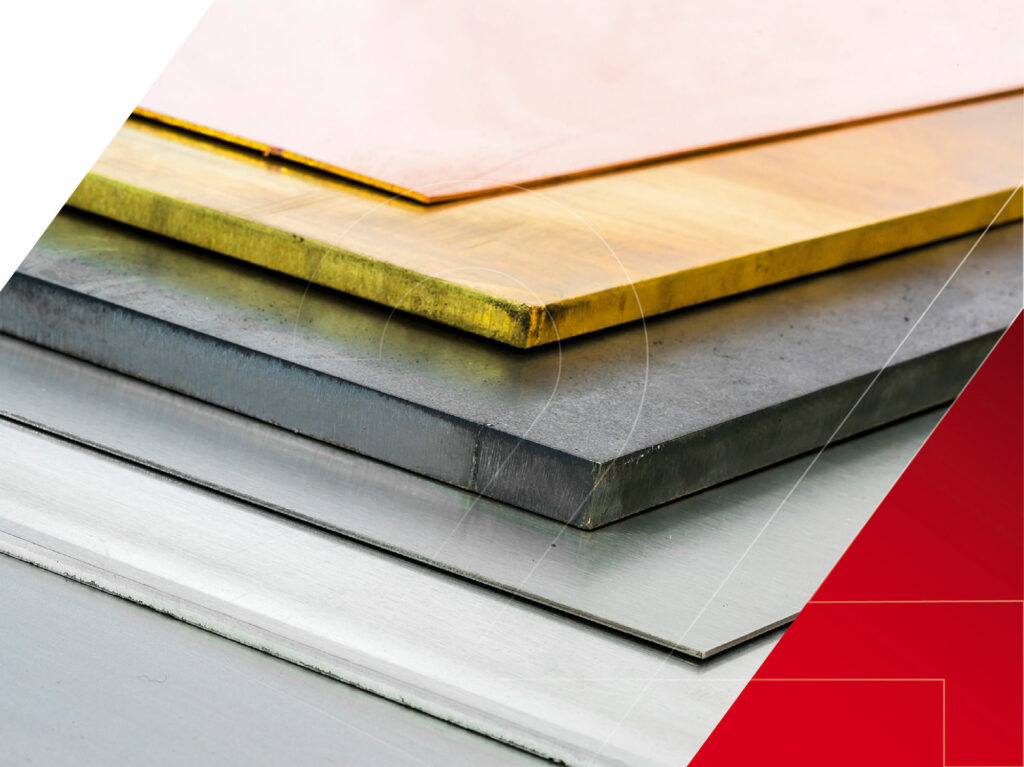

When it comes to laser cutting, selecting the right material is crucial for the success of your project. At Laser 24, we cut and fold a range of materials suitable for various applications across multiple industries. This guide will help you understand the properties and applications of each material we work with, ensuring you make the most informed decision for your laser cutting needs.

S275/S355 Mild Steel

S275 and S355 are grades of structural steel known for their affordability and versatility. Both are commonly referred to as mild steel and are distinguished by their yield strength: S275 has a yield strength of 275 N/mm², while S355 offers a higher strength of 355 N/mm². This makes S355 slightly more durable under heavy load conditions, making it ideal for construction and engineering projects.

Mild steel is an excellent choice for laser cutting due to its high-quality surface finish and ease of cutting. Applications are diverse, ranging from structural components and frames to machinery parts in the construction, transport, and agricultural sectors.

Our Cutting Thickness 3mm to 30mm

CR4 Mild Steel

CR4 stands for “Cold Reduced Grade 4” mild steel, known for its smooth surface finish. This material is cold-rolled, which increases its strength and hardness. CR4 is particularly suitable for applications where aesthetics are as important as functionality, such as in the automotive industry, where it is used for body panels and structural components.

Our Cutting Thickness 0.5mm to 3mm

Stainless Steel

Stainless steel is renowned for its corrosion resistance, making it ideal for use in environments prone to rust, such as in food processing and marine applications. It is also favoured for its aesthetic appeal which makes it popular in architectural and consumer goods sectors. Laser cutting stainless steel requires precision, which Laser 24 delivers with state-of-the-art technology to ensure clean cuts and intricate detailing.

Our Cutting Thickness 0.5mm to 30mm

Aluminium

Aluminium is lightweight yet strong, with excellent corrosion resistance and conductivity. It is easy to machine and weld, making it a preferred choice for industries including aerospace, automotive, and electronics. Aluminium’s lightweight nature makes it ideal for components where reducing weight is critical, such as frames and panels in transport vehicles.

Our Cutting Thickness 0.5mm to 30mm

Brass

Brass is an alloy of copper and zinc, known for its malleability, acoustic properties, and resistance to corrosion. These properties make it an excellent choice for decorative elements, musical instruments, and general hardware. The reflective nature of brass can pose challenges for laser cutting, but with Laser 24’s advanced laser cutting technology, we ensure high precision and quality finishes.

Our Cutting Thickness 1mm to 15mm

Copper

Copper is highly conductive, making it indispensable in the electrical industry for components such as busbars and switchboards. It is also used in the construction of decorative elements due to its distinctive red-orange colour. Copper’s thermal and electrical conductivity means that special attention must be given during the laser cutting process to prevent warping and ensure accuracy.

Our Cutting Thickness 1mm to 12mm

Zintec

Zintec is a cold-rolled steel coated with a thin layer of zinc to protect against corrosion. It is often used in the automotive, domestic appliance, and construction industries where additional corrosion resistance is required without the need for stainless steel. Zintec is suitable for laser cutting, and its coating helps maintain material integrity during the process.

Our Cutting Thickness 0.7mm to 3mm

Galvanised Steel

Galvanised steel is regular steel coated with zinc to offer enhanced rust protection. It is frequently used in outdoor applications, from construction and automotive to utility and communication equipment. Galvanised steel can be more challenging to laser cut due to the risk of zinc fumes, but at Laser 24, we employ advanced techniques to ensure a safe and clean cut.

Our Cutting Thickness 0.7mm to 5mm

Choosing the Right Material for Your Industry

Each material has its unique set of properties that make it suitable for specific applications. When selecting a material for laser cutting, consider the mechanical and chemical properties required for your application.

Choosing the right material is just the beginning. Contact us today to discuss your project requirements, and let us help you select the perfect material to match your needs, ensuring durability, functionality, and cost-effectiveness.