When you work with sheet metal, speed, efficiency, volume, accuracy and intricacy are five significant areas where laser cutting can surpass any other method in the production of metal parts. All these elements are required within the construction industry putting laser cutting at the top of the list for the manufacture of modern buildings.

The lowdown on laser cutting

Operated under the expertise of specialist programmers, the cutting equipment uses a fibre laser which can cut metals up to 30mm thick. In the UK, our capabilities outstrip most other contractors, and we are one of only a few laser companies who can work with mild and stainless steel and aluminium at 30mm, brass at 15mm and copper up to 12mm. In the world of modern construction, metalwork is a substantial part of production and every millimetre counts.

Why does the construction industry use laser cutting?

The list of reasons is long and impressive. The construction industry works to tight deadlines, and often needs parts supplied in large quantities. Laser cutting can produce these parts at speed and in high volumes making it an incomparably efficient option. Because of these dual factors, it also makes it a very cost-effective choice which is essential for ensuring projects come in on budget. To expand on budgetary concerns, the accuracy of laser cutting also reduces waste – another win for cost management. This, in turn, has benefits from an environmental standpoint. It provides focus and is a smooth process. Its relevance is unique.

The list continues…

Let’s not underestimate the importance of safety. Laser cutting has higher safety standards than traditional construction methods – there’s no risk of spinning blades or flying debris with laser cutting and dust and fumes are limited too.

What parts can laser cutting produce?

Laser cut metal is an integral part of modern construction. At the larger end of the scale it produces structural steel like steel beams and columns which are used on everything from bridges to residential and commercial buildings. Connection plates and base plates are also successfully manufactured by laser cutting as is architectural metalwork like railings, panels and balustrades.

A new era for decorative features

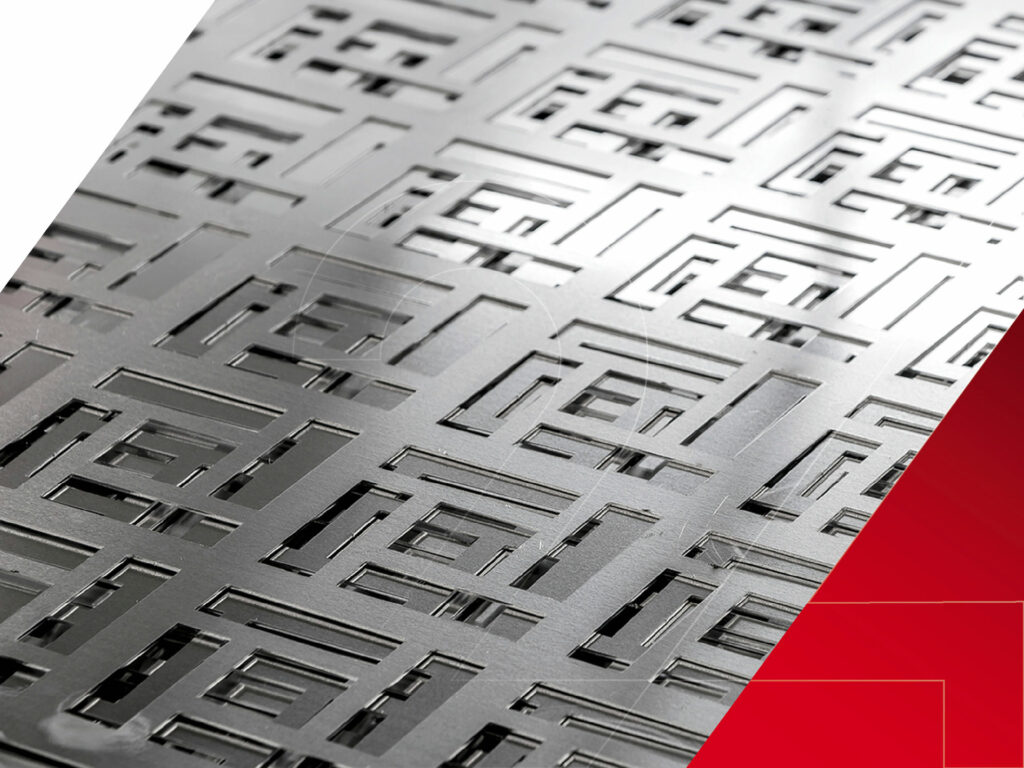

As well as high volume structural pieces, the precision of laser cutting makes it the superior choice for more intricate decorative features. Bespoke production is easily achieved and thanks to the efficiency of the technology, even one-off pieces can be created without delay. Many of the intricate pieces produced by laser cutting could never be recreated manually, widening the field of design possibilities.

Not all laser cutters are made equal

We use Bystronic ByStar 10kW and Bystronic ByStar 12kW fibre lasers which cut metal in record time. They are Swiss made to the highest quality and are exceptionally precise. To support the metal cutting process, we have also invested in smart factory automation meaning production can run 24/7. State-of-the-art software including touch screens, and smartphone capabilities increase production speed even further.

Let’s not forget the importance of press braking

In the world of metalwork and high-speed laser cutting it’s difficult to not also mention the importance of press braking. Used to shape and bend metal sheets, it’s another highly important tool for creating structural components like beams, roofing elements, staircases, brackets, reinforcement bars and window frames. It’s often used in conjunction with laser cutting and at Laser 24 we are skilled in both.