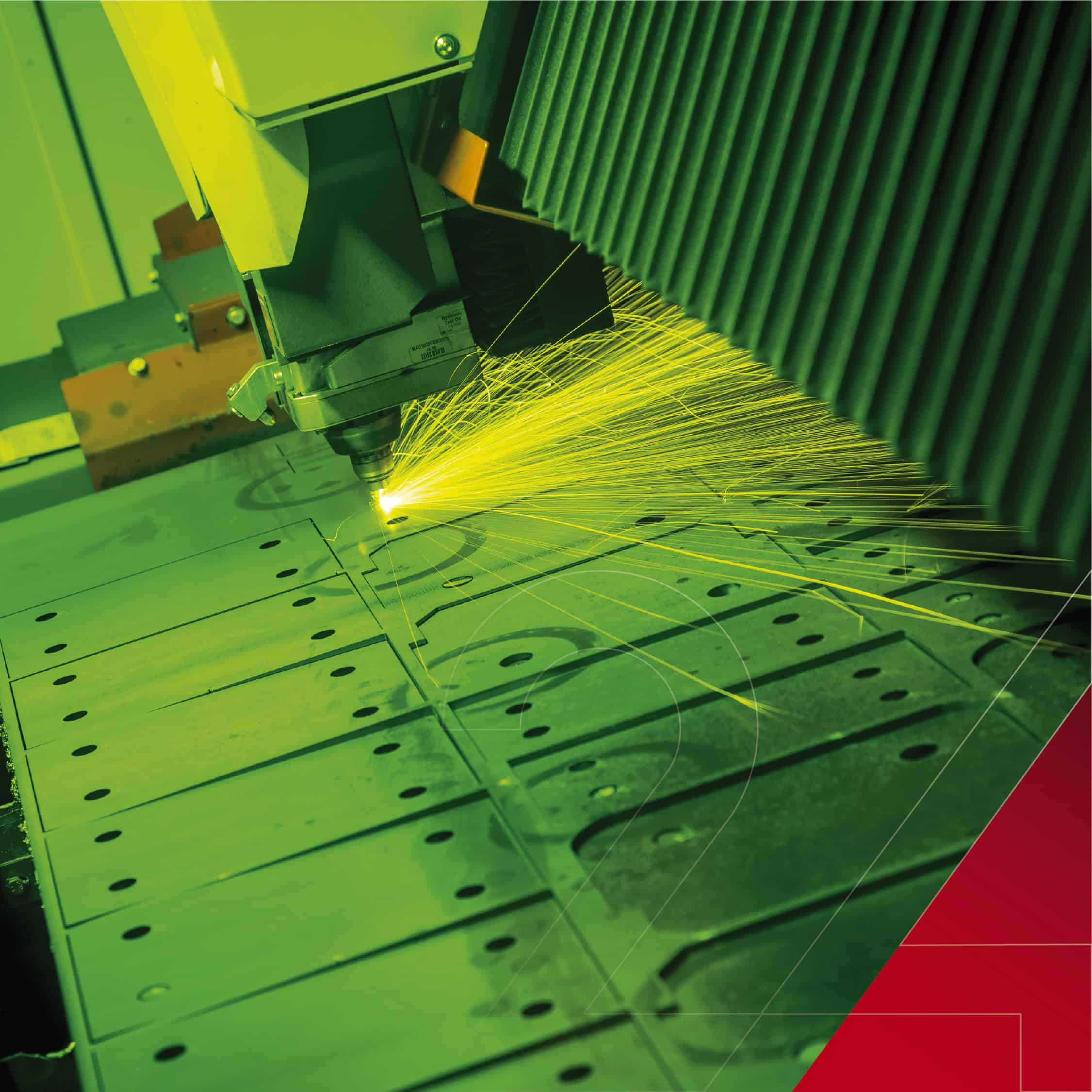

With our state-of-the-art Bystronic ByStar Fiber 12kW laser now in full production, the next generation of laser cutting has truly arrived here at Laser 24!

The past few years have seen huge technological advancements in laser cutting technology, with the latest range of Bystronic lasers setting a new benchmark in the industry. Keen to stay one step ahead, Laser 24 has been an early adopter of their most powerful models, commissioning two of their 10kW lasers in 2019, before investing in their high-tech 12kW laser this year.

Today, we are the proud owners of the ByStar Fiber 12kW, thanks to our ongoing investment project to deliver unrivalled production capabilities to our valued customers. Boosted by 12 kilowatts of laser power, each cut is faster, cleaner and more cost-effective than ever before, with cutting speeds of up 20% faster than its 10kW predecessor.

We share our favourite features of the new 12kW laser, to showcase the superior capabilities of this machine and how much it will revolutionise our production processes to create the highest quality parts for our customers.

Innovative ‘BeamShaper’ technology

An eagerly anticipated new feature on the 12kW is its innovative ‘BeamShaper’ technology, which guarantees a clean-cut edge on a wider variety of metals when processing with oxygen as the assist gas. The BeamShaper function effectively adapts the beam to a larger beam profile, creating a larger beamwidth for oxygen cutting of thick mild steel. Not only does this result in a higher quality finish on greater sheet thicknesses to rival a CO2 laser, the BeamShaper technology also increases the cutting speed by up to 20% – which means we have more capacity for your jobs and provide an even quicker turnaround time.

Cutting head improvements

The new, slimmer cutting head design ensures stability in the cutting process for an accurate, high quality finish, while optimal cooling in the cutting head will help maintain a precise cutting performance by protecting the lenses and cutting nozzle from high thermal stress.

Maximum precision in both thin and thick sheets and profiles

Without compromise, the high-performance equipment effortlessly cuts mild and stainless steel up to 30mm, aluminium up to 30mm, brass up to 15mm, and copper up to 12mm, as well as a range of materials. Prior to the arrival of the 12kW, our maximum thickness for cutting mild steel was 25mm, so we’re delighted that we can cut a greater range of thicknesses for our customers.

Laser 24’s Director, Iain Summerfield, shares his excitement here:

“The laser cutting industry has completely changed since I began my journey nearly 20 years ago. I believe that, by introducing our very latest machine, we have the best machines to handle the laser cutting needs of not only our current customers, but future customer requirements as well.

I know we have invested in the right equipment to ensure the highest quality laser cut parts in all thicknesses up to 30mm thick. This was impossible only a few short years ago and I am proud that Laser 24 can now achieve offer this.

Exceeding our customer’s expectations has always been the driving force for any investment decisions. To have the ability to cut up to 30mm thick mild steel with a superior edge quality allows our customers to reduce their own costs by removing secondary operations from their production line. By investing in our technology and expertise we are future proofing Laser 24 to handle any size project by producing superior quality parts by the best team.”

By further improving our productivity and efficiency, we can now help even more manufacturers complete their jobs faster. We know that having the best lasers for the best level of service is key, so we’re excited to see just how much the new 12kW laser will transform production here at Laser 24.

Laser 24 are one of the top laser companies in the UK. Explore all our laser profiling capabilities here. To find out how we can help you with your next manufacturing project, please call our team on 01268 733883.