Technological developments in press braking have revolutionised the way that industries operate, allowing for a whole manner of metals to be seamlessly bent and folded into new shapes and forms. Whether it’s a quirky one-off design or a high-volume production of equipment, press braking provides a speedy solution that helps businesses create all the metal parts they need for any project.

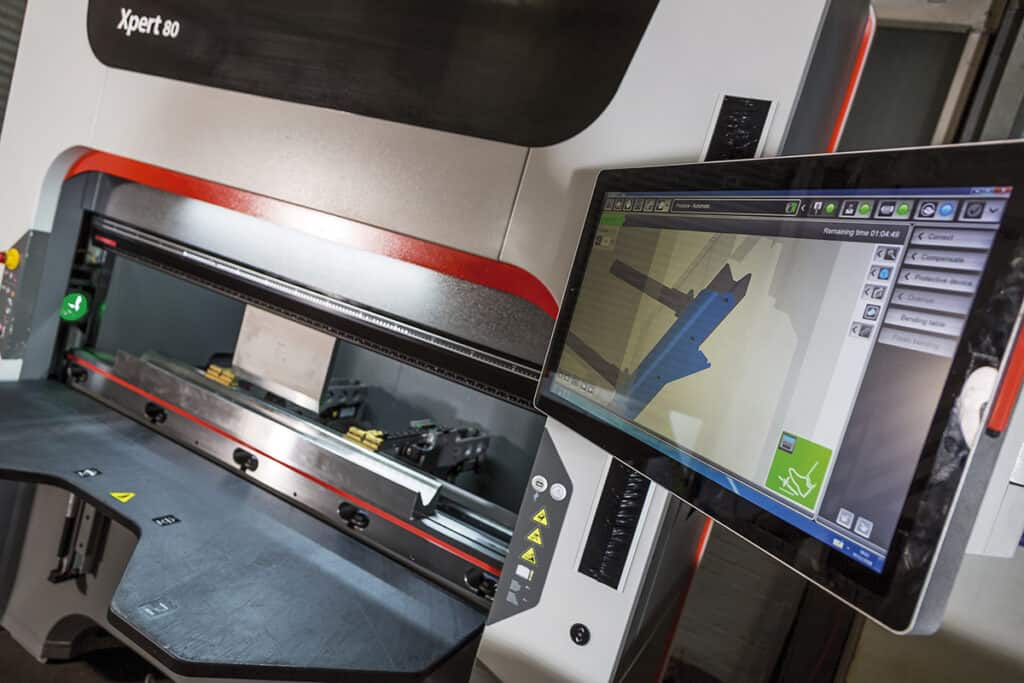

Combined with our laser cutting services, press braking allows for the most complex and innovative designs to take shape! That’s why we have invested in the highest industry benchmark in press braking for our customers’ requirements – the Bystronic Xpert 80. In this post, we explain how press braking works and how it continues to bring brilliant benefits to businesses.

Read on for more about press braking with Laser 24 below…

Why is the Bystronic Xpert 80 the ideal press brake?

- Compact speed machine for small and medium-sized parts, making up all the pieces larger projects

- Flexible tool selection and press capacity of up to 80 tons to offer a wide range of applications

- Maximum process speed via high acceleration of the upper beam and back gauge

- Process controlled reduces electric power consumption by up to 30 per cent

- Decreases wear on the metals in comparison to alternative methods

- A high ease of use through ergonomic design and individual customisable work environment

Affordable press braking solutions for the cleanest parts

Latest innovations in press braking mean that we can provide a cost-effective and speedy solution that leaves metals in tip-top condition!

Our Bystronic Xpert 80 uses hydraulic operation which allows for versatile air bending. This offers us a highly accurate, zero-handling method that is non-abrasive to the metal. The process is also super-fast and extremely energy efficient, for rapid turnaround times on every project and cost savings that are passed onto our customers.

Bending all the metals: including sheet metal

With a bending length of 1.5 metres and a press capability of up to 80 tons, our press braking machinery allows for a whole manner of materials and thicknesses to be contoured and manipulated into new forms. Combined with our leading SolidWorks and Bysoft 7 programming systems, folding tricky materials is no longer an issue!

Most commonly used for sheet metal, press braking offers a wide application to various materials, including aluminium, brass and stainless steel. But because it is so dynamic, the varying metal thicknesses require distinctive programming and tooling resulting in different radius. No two metals or project will be treated the same!

Plus, we are laser cutting experts, so having a laser cut metal part-folded has never been easier! Our advanced ByStar 10kw Fibre Laser is the perfect partner to our press braking services. Whether it’s the simplest of folds to a more complex design, our press brake can handle all the requests with exact precision every time! So, the advantages of laser cutting combined with the benefits of press braking are endless.

Press braking experts for your project

Every industry has its own requirements, so it is critical that you have a press braking expert by your side that understands those needs. That’s why our press braking team have years of experience that acquires the ability to read and interpret engineer drawings, calculate fold angles and dimensions, and to see any project through from start to completion without error. We work with a wide range of sectors, including commercial retail, Ministry of Defence, property, medical and the automotive industry.

Safety and wear resistance are our first priority when producing metal parts for our customers, so we always produce highly reliable equipment for any task at hand. The detail is critical when producing parts in the public sector, such as yellow goods for a construction project, or metals being used by medical facilities. Whether it’s metal brackets for retail or equipment for large-scale projects, each of our metals is securely designed to meet a planner’s exact requirements.

Get your press brake quote today

Our press braking services are a core part of our holistic approach to every project, allowing for metal-cut parts to be taken to new ‘dimensions’. With our extensive range of tooling and state-of-the-art software, latest innovations in press braking continue to make the unimaginable come alive!

We work alongside our customers to come up with the best solutions to getting the job done at a cost-effective price. We don’t just ‘do’ what we are asked – we are consultants and are happy to help put together drawings for bending, to calculate accurate data, and to produce custom bent materials if required.

Laser 24 are one of the leading laser companies in the UK. If you have a project you’d like us to help you with, let us know your press braking requirements by calling us on 01268 733883, emailing [email protected] or request your 24 Quick Quote today.