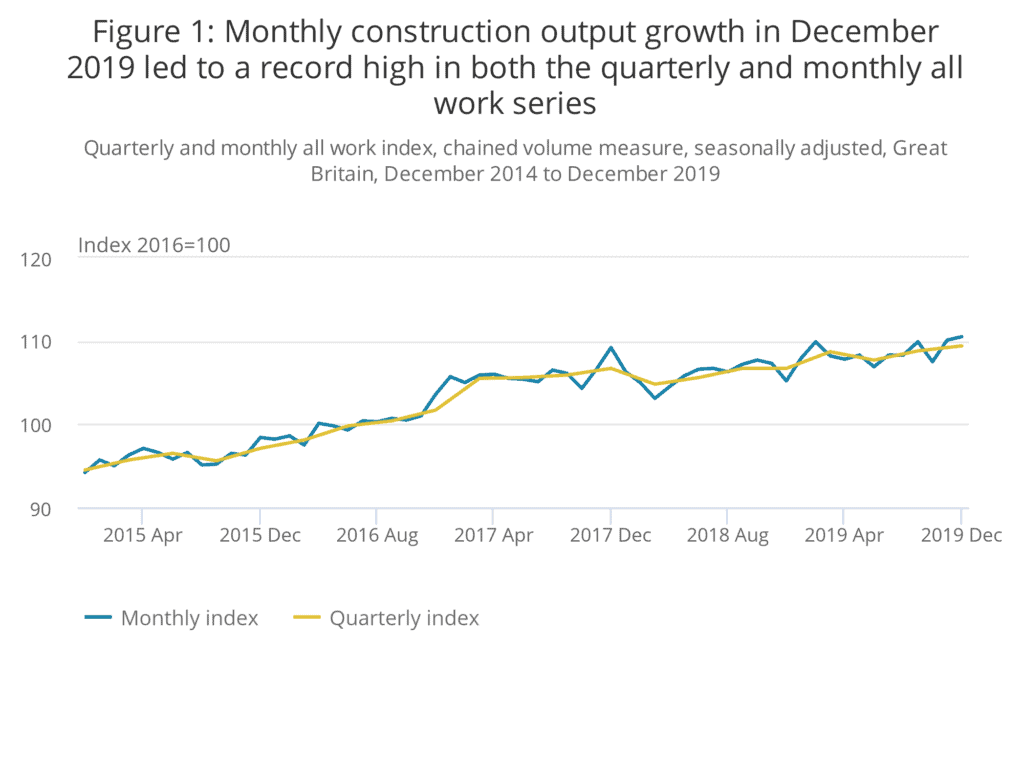

According to the Office for National Statistics, the Manufacturing industry’s output fell by 1.1% in the last quarter of 2019, yet the Construction industry stabilised. In fact, it’s estimated that Construction output increased by 0.5% from Quarter 3. This growth reflects the strength of the Construction sector and is encouraging for developers involved in new projects, especially in private commercial and public housing.

In particular, London and the South East are forecasted to have above-average productivity in 2020, bucking the trend compared to the rest of the UK. With this demand in mind, UK Construction companies must adopt new, innovative solutions to streamline their work and stay ahead of competitors.

Laser cutting and press braking have transformed the way the Construction sector operates, providing a modern, effective solution in the production of metal parts.

With the fourth industrial revolution upon us, the automated capabilities of modern laser cutting technologies are set to take laser cutting for the Construction industry to new heights, playing an integral part in revolutionising the way vital infrastructure is built.

From cost-cutting to time and energy saving, we explore the role laser cutting technology plays in the innovation of UK construction:

Cutting time and cost

Construction companies have to make smart decisions to remain competitive in the landscape of ‘Industry 4.0’. To keep costs down and productivity up, many businesses are now turning to laser cutting and press braking solutions to improve the speed of production and increase operational control.

Laser cutting and press braking provides speedy solutions for companies that require a high volume of parts for a large-scale project, and likewise for one-off jobs that require a higher level of intricacy.

Using all manner of metals

Thanks to the advanced technologies in laser cutting, construction companies can now experiment with metals aside from steel, at varying thicknesses that were not previously conceivable. In fact, laser cutting can deliver anything from simple to complex parts in small to large batches.

We can laser cut an impressively wide range of material thicknesses, from 0.5mm right up to 30mm – depending on your desired metal. As well as stainless steel and mild steel, which are most commonly relied upon in the industry for building materials, laser cutting also makes it possible to cut non-ferrous metals such as aluminium, brass and copper with ease.

Taking tech to the next level

Architects and construction teams will continue to take advantage of digital transformations in 2020. As cities modernise, with the aesthetics of the buildings and landscape being an important part of the process, construction projects are becoming even more complex throughout the UK. Construction project planners are relying on experts that can outsource bespoke part production for unique designs and structural builds.

Combined with software and programming, advanced laser cutting technologies are helping architects and construction teams improve designs and detect any errors.

From hand drawing to calculating data and computing CAD/CAM drawings, laser cutting specialists can help architects and construction teams get their project briefs together. With an extensive range of tools and state-of-the-art software on the market, laser cutting can provide the latest innovations to make the unimaginable come alive, all while remaining accurate, compliant, and on budget.

At Laser 24, we use a range of innovative software to calculate cutting plans and bending processes with optimum accuracy, and even the most complex designs can be executed by bystronic laser cutting. We have the capacity to produce intricate or identical parts with to-the-millimetre accuracy, so you can rely upon us to provide the parts needed for the soundest of structures. All our work also conforms with the highest industry standards for health, safety, and environmental protection for construction products, as demonstrated by our ISO 9002:2015 accreditation and full CE Certification to Execution Class 4.

Constructing a greener world

With environmental concerns topping the public agenda and many companies setting carbon footprint reduction targets, the construction industry is having to make considerable efforts to optimise energy efficiency and improve sustainability going forward.

Laser cutting and press braking provide an energy-efficient production solution for construction and architectural industries, as it not only cuts down their carbon footprint but also reduces metal waste.

Using nitrogen, oxygen, scan, and air, Laser 24’s processes use much less energy when cutting metal compared to other solutions. Our machines have been developed to reduce electric power consumption by up to 30% during use compared to other industry equipment, which ultimately results in further cost savings for our customers!

Read more about our mindful working practices here.

Pre-fabricating future builds

Pre-fabricated construction is an innovative practice that will become increasingly popular in the decade ahead. Pre-fabrication involves assembling a variety of precision-cut components, to be assembled using tab and slot techniques. The construction industry will look to keep builds off-site, instead having them delivered practically ready-to-build.

Pre-fabrication takes much of the work from the construction site, improving the speed and ease of the project.

Laser 24 can produce tab and slot metal parts with ultimate accuracy for pre-fabrication manufacturers. Our quick turnaround times and automative capabilities mean you can rely on us to provide you with your critical construction parts at rapid speed, without compromising on quality.

We are one of the leading laser companies in the UK. If you require high speed laser cutting solutions for your construction project, we’d be happy to help. Get in touch today by calling us on 01268 733883, emailing [email protected] or by requesting your 24 Quick Quote.